Combined treatment and sorting plant for residual waste, Hengelo

In 2015 Twence launched a project for a combined residual waste treatment with the focus on the recovery of secondary raw materials for recycling. The scope of HTP's engineering service in 2015 was the construction and operation of a residual waste treatment plant with an integrated sorting facility for the production of secondary raw-material products which are internationally marketable. Products generated include dry recyclables consisting of metals, plastics (diversified) and paper or paper composites as well as an RDF-fraction.

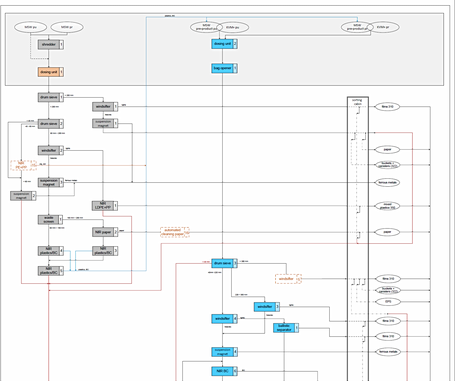

For this purpose, a process concept was developed and brought to tender that uses state-of-the-art processing technology for this sector. A high level of automation was an important planning premise.

HTP was commissioned to provide the engineering service for this combined plant and supported the project up to the point it was awarded after an EU-wide participant competition and public tender procedures. After being awarded, the project was not realized for economic reasons.

PROJECT CHARACTERISTICS

Capacity: 250,000 t/a

Design: Mechanical residual waste treatment plant with integrated sorting of recyclable materials

- Conditioning by screening

- Wind-sifter steps

- Manual sorting for film

- Automatic picking systems for 6 fractions

- Suspension magnets and eddy-currents to generate metal products

Products:

- Film 310

- Metals Fe und NE

- Beverage carton 510

- Plastic types: PE, PP, PET

- Mixed plastics

- RDF for combustion

Company: Twence

Simplified process flow diagram

Location, Source: Twence